Hapag-Lloyd Shipshave trial yields positive results

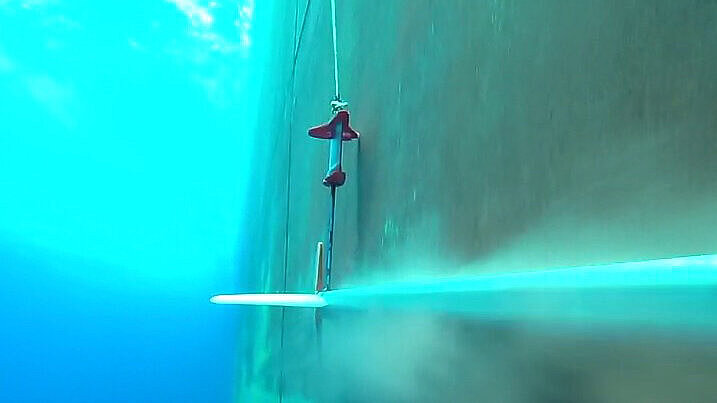

Scratching the ITCH: Shipshave’s hull cleaner in action (Source: Shipshave)

Hapag-Lloyd has reported success with the Shipshave hull cleaning system, which consists of a deck winched-launched hull cleaning ROV that uses fins to shimmy up and down the side of the vessel, while the motion of the vessel pins it to the hull and keeps the brush on target, cleaning off hull fouling.

Deriving all of its oscillating movement from the motion of the vessel, energy requirements for the ITCH are lower than conventional hull cleaning ROVs, and reduce hull cleaning downtime for the vessel.

While the system cannot clean the bottom, bow, or aft propeller section, substantial gains can be made from cleaning the hull sides, which together make up the majority surface area of the underwater hull, as well as saving time during alongside hull-cleaning operations. In-transit cleaning also allows for more regular cleaning operations, creating a snowball effect of improved performance.

A DNV study on two Hapag-Lloyd container vessels, occurring over a 17-month period, highlights the extent of this hull cleaning, with a 16% improvement in performance exhibited as a result of near-continuous hull cleaning with Shipshave, and 5% in the other case.

“We are very pleased that this analysis from DNV confirms our internal assessment of the result achieved by the implementation of ITCH,” said Nikhilesh Bhatia, Fleet Energy Efficiency director, Hapag-Lloyd. “This method reflects our proactive approach to reducing emissions caused by biofouling.”