PPG in milestone 50th spray

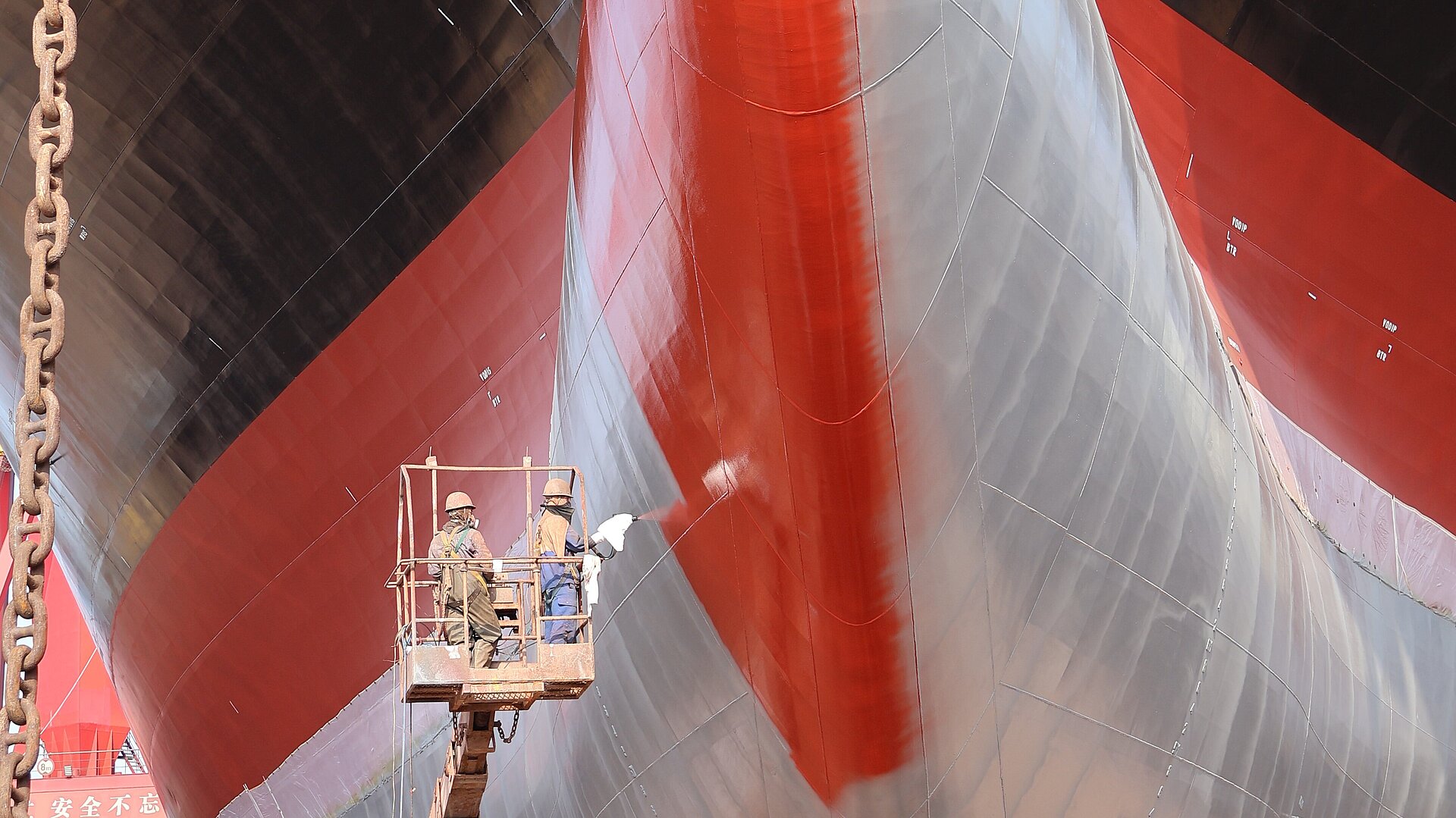

The electrostatic process promises a more uniform application of hull coatings, meaning more efficacy and less waste (Source: PPG)

US-listed PPG has applied its milestone 50th electrostatic application of a marine fouling control coating, on VLCC Sidr, a 336m-long oil tanker managed by Bahri Ship Management, with PPG Nexeon 810 antifouling coating at Oman’s Asyad Drydock Company.

The understanding is growing throughout the industry that a coating, however technologically advanced, is only as good as its application. Electrostatic coating, adapted from aerospace and automotive sectors, is a precise coating application process which reduces overspray and material waste, PPG said.

Unlike traditional airless spraying, the technique uses electrically charged paint particles directed at a grounded hull to create a uniform finish. Both PPG’s Nexeon and Sigmaglide series coatings can be applied using this technique.

Sustainability and compliance are driving adoption. Khalid Alhammad, Bahri’s president of ship management, emphasised the environmental benefits, noting the reduced carbon footprint and enhanced operational efficiency. “This technology aligns with our fleet’s emission reduction goals,” he said.

Shipyards also benefit from cleaner workspaces and cost savings. A recent project at EDR Antwerp shipyard saw a 40% overspray reduction. PPG’s approach offers a compelling solution for shipyards and operators held to ever higher environmental standards.